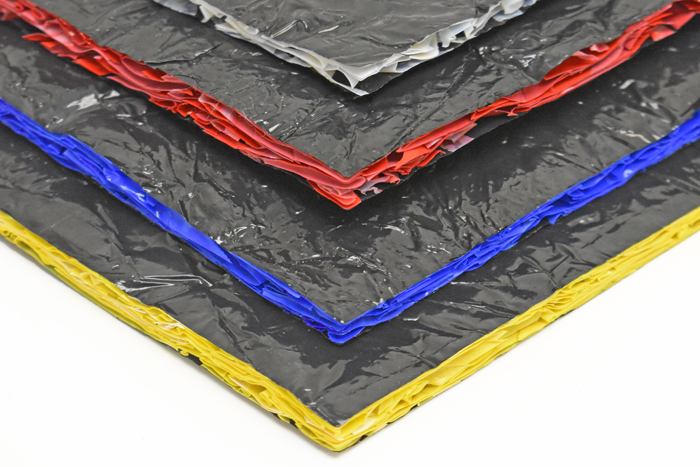

An award-winning cross-pattern laminated PTFE film for use in extreme environments.

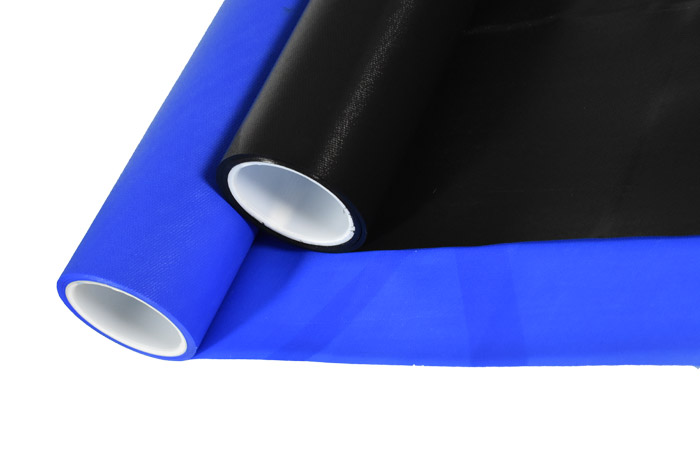

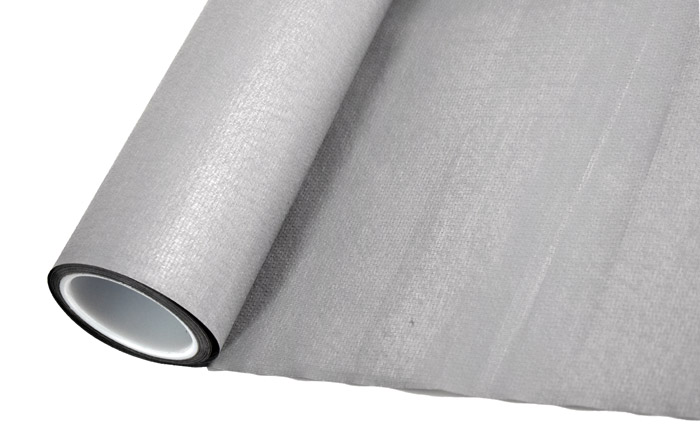

TCI’s CrossFilm™ is a 100% PTFE material that is guaranteed corrosion and contamination free, resists tearing, and has superior flexing capabilities compared to other PTFE products. CrossFilm™ can be heat-sealed and is unaffected by UV exposure or moisture.

Because this is an all-PTFE product with excellent mechanical capability and multi-directional strength, CrossFilm™ does not require any compromising reinforcement. Regardless of chemical exposure, CrossFilm™ remains corrosion free and non-flammable. CrossFilm™ has proven in laboratory and industrial settings its ability to retain all its physical properties regardless of chemical environment.

TCI’s proprietary CrossFilm™ process uses a cross-pattern typically created from 3 mil or 4 mil film plies to produce a material with exceptional 360° tear strength and durability. Because CrossFilm™ consists solely of PTFE resins, the product is considered chemically inert and can be used in temperatures ranging from -425°F (-254°C) to 600°F (316°C), depending upon the thickness of CrossFilm™ used. CrossFilm™ has an unlimited shelf life and is compatible with all chemicals.

Downloads

Related Applications