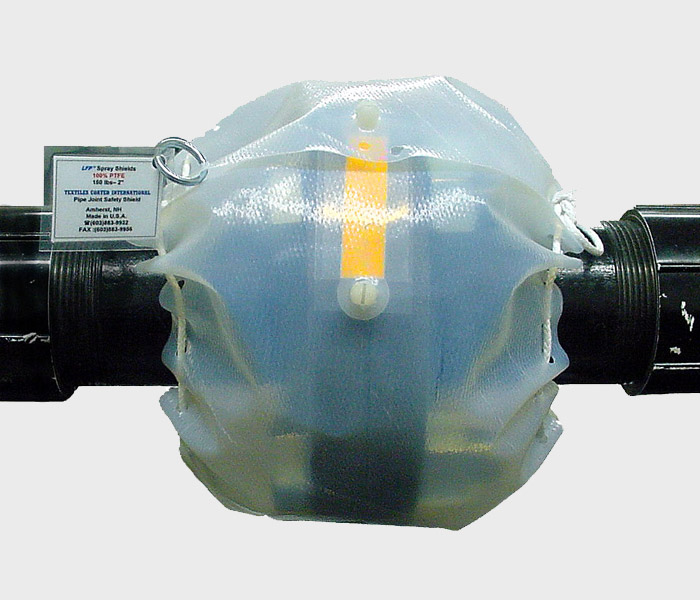

Spray Shields

Using non-porous, all-PTFE CrossFilm™ spray shields guarantees performance against harmful spray out and leakage regardless of the severity or duration of chemical exposure. The versatility and cost-effectiveness of this type of spray shield allow it to be used in almost all industrial settings, including marine, offshore, pharmaceutical, chemical processing, FDA-approved, cryogenic, and clean room applications.

Unlike our award-winning CrossFilm™, many spray shield materials, including PTFE-coated fiberglass, can be weakened by challenging industrial environments and often require monitoring. With a TCI CrossFilm™ spray shield, the body and drawstrings are all made of 100% PTFE. Because PTFE is unaffected by even the most corrosive chemical environments, CrossFilm™ spray shields ensure worker safety will not be jeopardized by degraded materials in the event of a spray-out at a flange. The curl over design of TCI spray shields also inhibits side spray-out.

The translucent material used in a CrossFilm™ spray shield allows safe and easy detection of moisture leakage at a flange. If leakage does occur, the spray shield can be cleaned and reused without concern for weakening due to chemical attack.

CrossFilm™ spray shields can be used in a pH range of 1-14 and a temperature range of - 425°F (-254°C) to 600°F (316°C) for constant exposure. TCI spray shields remain unaffected by UV, moisture, or chemical exposure. Our CrossFilm™ material has zero porosity, and the one-piece design ensures no leakage. TCI can customize spray shields with specific sizes or other additions, such as drain nipples, by request.