Due to superior chemical resistance to most acids and solvents, PVDF films are used as a contact surface for the production, storage, and transfer of corrosive fluids. Applications include chemical tank linings, pump diaphragms, water treatment, and chemical storage bags.

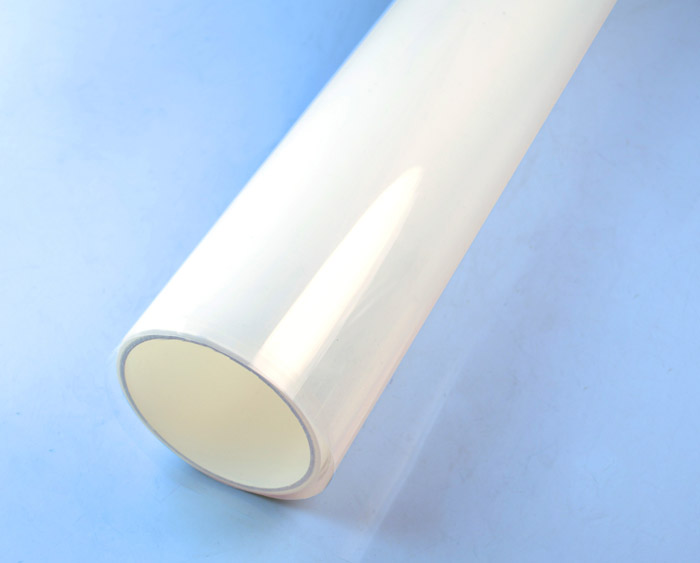

PVDF Films

TCI’s PVDF films/foils are produced from Polyvinylidene Fluoride resins using a melt extrusion casting process. PVDF foils offer all the benefits of fluoropolymer films, such as resistance to harsh thermal, chemical, and ultra-violet environments, excellent weatherability, non-stick properties, and superior dielectric performance. PVDF films can be heat-sealed, thermoformed, and laminated to various substrates.

PVDF films are chemically inert and resistant to most chemicals. They possess excellent abrasion and fire (UL V-0 rating) resistance. PVDF films have the superior anti-stick and low friction properties of a fluoropolymer, as well as high dielectric strength. These films also have outstanding weatherability and resistance to UV radiation.

PVDF films/foils can operate continuously at service temperatures up to 300°F (150°C). TCI produces our PVDF films in a variety of thicknesses between 0.001" to 0.010" (25 to 250 mμ), with a maximum standard width of 60” (1,524 mm). Any slit widths and bondable (plasma treated or chemically etched) surfaces are available by request.

Related Applications

PVDF films are additive-free, possess complete bio–medical and chemical inertness and very low levels of extractables. They are very flexible and easy to heat-seal. All of these attributes make them invaluable for sampling bags applications

Excellent weatherability, UV resistance, and abrasion resistance make PVDF films very effective for over-laminating billboards, traffic signs, and awnings.

Non-stick properties and excellent solvent resistance make PVDF films invaluable for covering high traffic areas that need to be frequently cleaned with aggressive solvents and cleaning solutions..

Due to their excellent dielectric performance, fire resistance, and high solar transmittance, PVDF films are very well suited for use in the back sheet and front sheet glazing of PV panels. They are used extensively as an external material for the back sheet, protecting the PV Module from the external environment for an extended period of time.