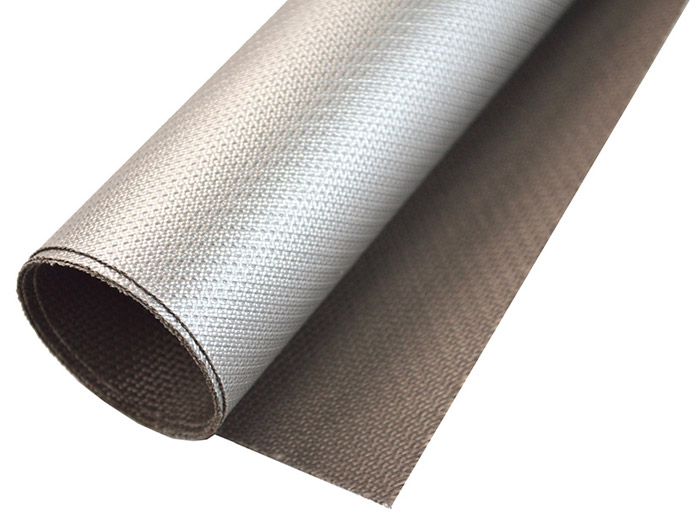

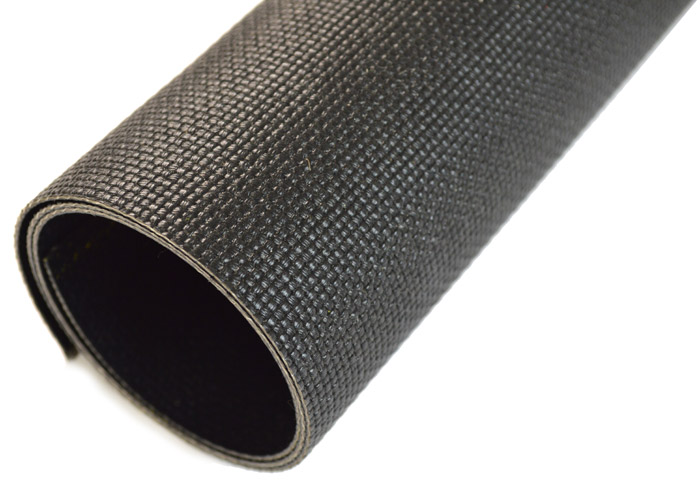

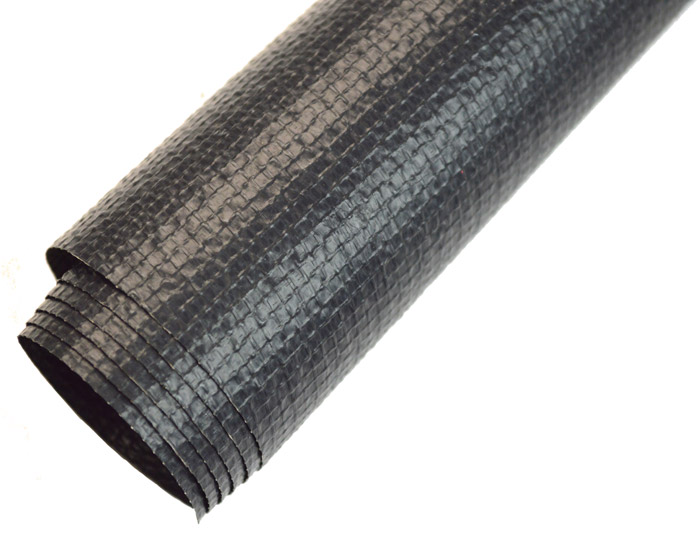

This CrossFilm™ laminate is designed for the most challenging applications. Using a proprietary hybrid of PTFE film and fiberglass, TCI's Hybrid™ material will simulate an all-PTFE laminate with the stretch and minimal elongation of a fiberglass reinforcement. It is ideal for high temperature service and wet, chemical environments. The tent-like texture and flexibility make it advantageous for the sewing of removable insulation jacketing and its superior adhesion properties ensure Hybrid™ belting will not delaminate or blister in food service applications.

Data Sheets

- Hybrid™ 7.0 Insulation Jacketing Materials

- Hybrid™ 8.0 Insulation Jacketing Materials

- Hybrid™ 6 Food Belting Series

- Hybrid™ 12 Food Belting Series

- Hybrid™ 14 Food Belting Series

- Hybrid™ 16 Food Belting Series

- Hybrid™ 210 Food Belting Series

- EM-Hybrid™