TCI's PFA Premium Grade (PG) films are manufactured from 100% virgin premium grade PFA resin with MFI range of 1.5-2.5. It is the grade of choice for dielectric applications, and/or where visual perfection

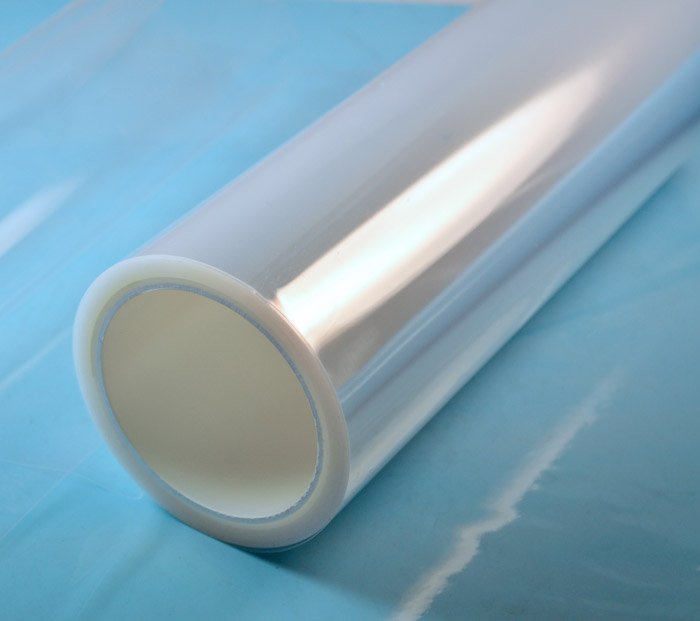

PFA Films

TCI uses a melt extrusion casting process to produce PFA films/foils from Perfluoroalcoxy (PFA) resin. TCI PFA films offer all the benefits of fully fluorinated films, such as a large continuous use temperature range (–425 to 500°F or -254 to 260°C), high chemical and stress crack resistance, and superior dielectric performance. These films have excellent light transmission and clarity and are free of plasticizers, processing aids, or additives. PFA foils can be heat-sealed, thermoformed, laminated to various substrates, and used as an excellent hot-melt adhesive.

TCI produces PFA films in thicknesses ranging from 0.0005" to 0.010" (12 to 250 mμ), with a maximum standard width of 60” (1,524 mm). Films thicker than 0.002” can be produced in widths up to 62” (1,575 mm). Any slit widths and bondable (plasma treated or chemically etched) surfaces are available upon request. PFA foils have a high dielectric strength: over 6,500 V/mil for 1-mil film (260 kV/mm for 25-micron film).

PFA film is chemically inert and solvent resistant to virtually all chemicals. It is best suited for applications where the combination of high temperature resistance and high chemical resistance is required, such as chemical pumps, tank linings, shrink roll covers, rupture discs and gaskets. PFA films also possess excellent dielectric properties over the widest range of frequencies and temperatures, making them invaluable in circuit board laminates and wire & cable insulation applications.

PFA Welding Grade (WG) films offer the same physical, mechanical, and thermal properties of PFA PG films at a 15-20% cost savings. This makes PFA WG films the perfect economical solution for heat sealing, welding, and other melt adhesive applications without high aesthetic requirements.

PFA Film Applications

- High-Performance Fluoropolymer Films Product Line

- PFA Data Sheet

- FEP & PFA Welding Grade Films

- FEP & PFA Architectural Welding Films Data Sheet

- TCI’s High-Performance Films for Gaskets and Sealing Solutions

- TCI’s High-Performance Films for Composite Hose and Flexible Duct Manufacturers

- TCI's Pilot Film Extrusion Line