Spray Shields

Using non-porous, all-PTFE CrossFilm™ spray shields guarantees performance against harmful spray out and leakage regardless of the severity or duration of chemical exposure. The versatility and cost-effectiveness of this type of spray shield allow it to be used in almost all industrial settings, including marine, offshore, pharmaceutical, chemical processing, FDA-approved, cryogenic, and clean room applications.

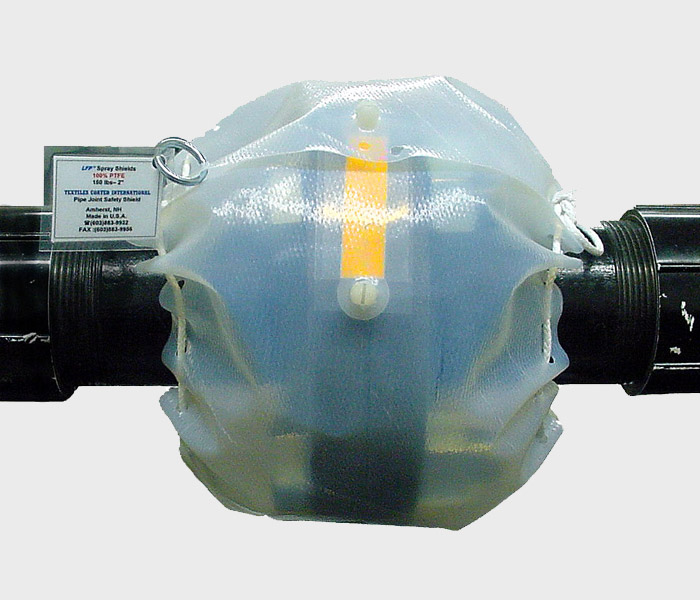

Unlike our award-winning CrossFilm™, many spray shield materials, including PTFE-coated fiberglass, can be weakened by challenging industrial environments and often require monitoring. With a TCI CrossFilm™ spray shield, the body and drawstrings are all made of 100% PTFE. Because PTFE is unaffected by even the most corrosive chemical environments, CrossFilm™ spray shields ensure worker safety will not be jeopardized by degraded materials in the event of a spray-out at a flange. The curl over design of TCI spray shields also inhibits side spray-out.

The translucent material used in a CrossFilm™ spray shield allows safe and easy detection of moisture leakage at a flange. If leakage does occur, the spray shield can be cleaned and reused without concern for weakening due to chemical attack.

CrossFilm™ spray shields can be used in a pH range of 1-14 and a temperature range of - 425°F (-254°C) to 600°F (316°C) for constant exposure. TCI spray shields remain unaffected by UV, moisture, or chemical exposure. Our CrossFilm™ material has zero porosity, and the one-piece design ensures no leakage. TCI can customize spray shields with specific sizes or other additions, such as drain nipples, by request.

As well as manufacturing CrossFilm™ spray shield, TCI offer additional materials for spray shield manufactures. These materials include ECTFE, ETFE, and FEP films. ECTFE is an excellent product for spray shields due to its superior chemical resistance to most acids and solvents over a broad temperature range and low permeability to solvents and gases. ETFE film has the same low permeability to liquids, gases, moisture, and organic vapors. Like other fluoropolymer films, FEP is chemically inert and solvent resistant to most chemicals.