Composite Molding Process

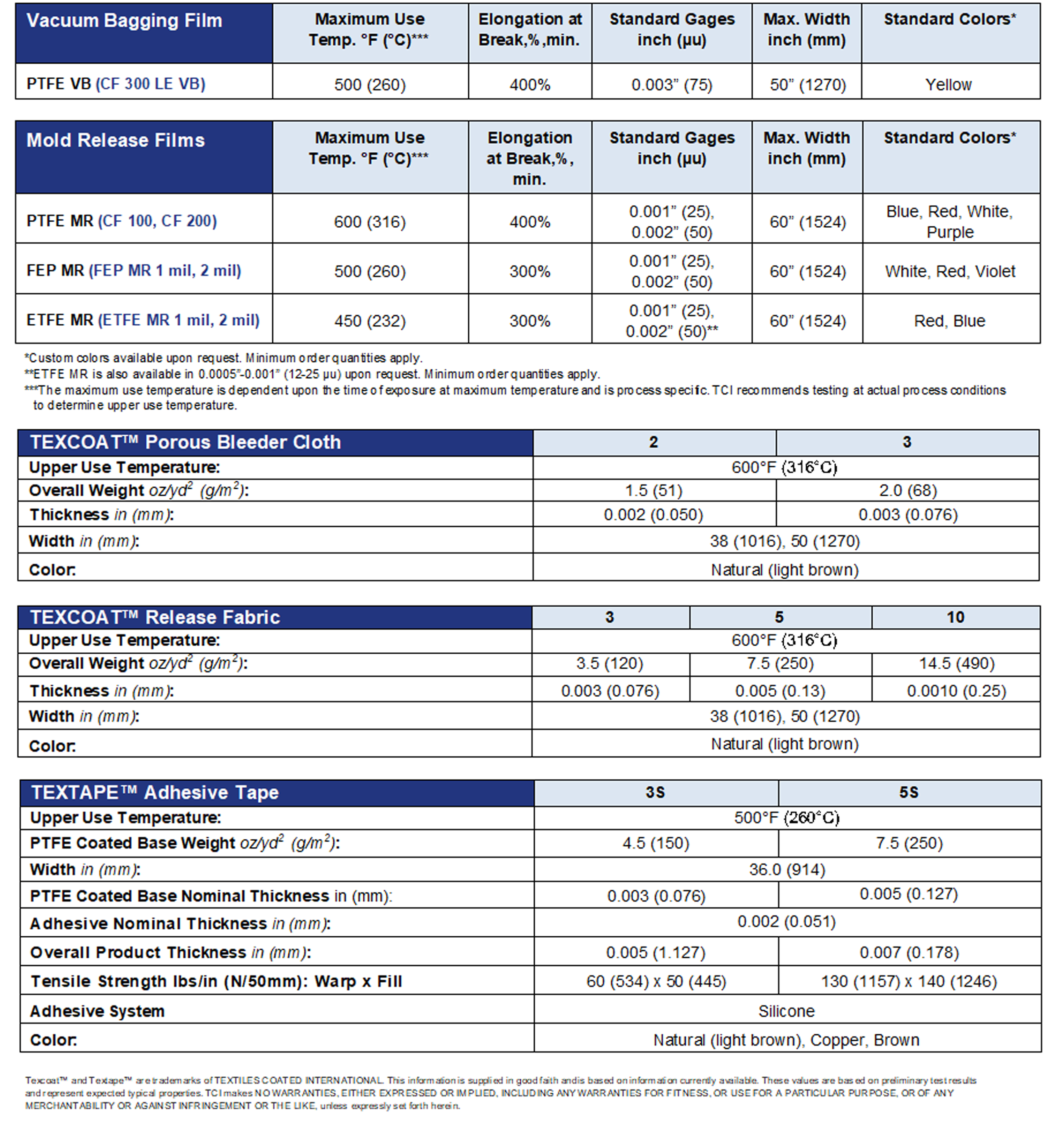

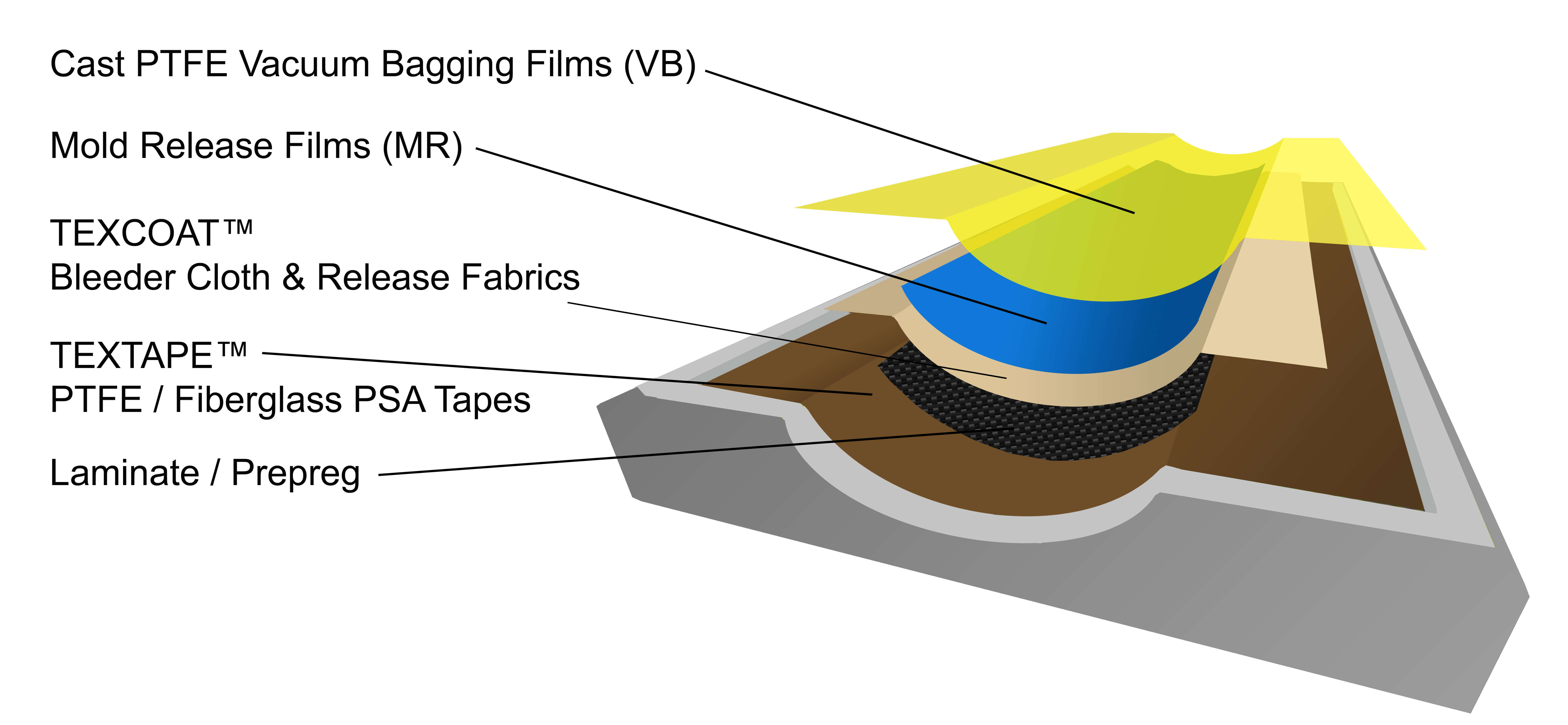

TCI offers a complete range of composite process molding materials and products for the high-end composite molding industry, including mold release (MR) and vacuum bagging (VB) films, PTFE coated fiberglass bleeder cloth, release fabrics, Edge Breathers, and breather fabrics. Our composite molding films are designed to withstand extreme temperatures while maintaining their release characteristics and are available in various colors to allow for easy identification. TCI’s mold release films (MR) for composite molding combine the chemical inertness and universal non-stick properties of PTFE polymers with maximum conformability and heat resistance. Our MR and VB films can withstand the highest temperatures in the composite molding temperature range, making them ideal for use in the aerospace, wind turbine, and automotive industries.

TCI’s FEP, ETFE, and MR films are ideally suited for carbon fiber molding because of their ability to withstand high temperatures and maintain release characteristics; these fluoropolymer films can also be used for release and chemical barriers in direct contact with the composite part. All of TCI’s films have a wide temperature range, chemical inertness, excellent weatherability, flame resistance, and anti-stick properties. TCI also offers perforated options of our fluoropolymer films called P3.