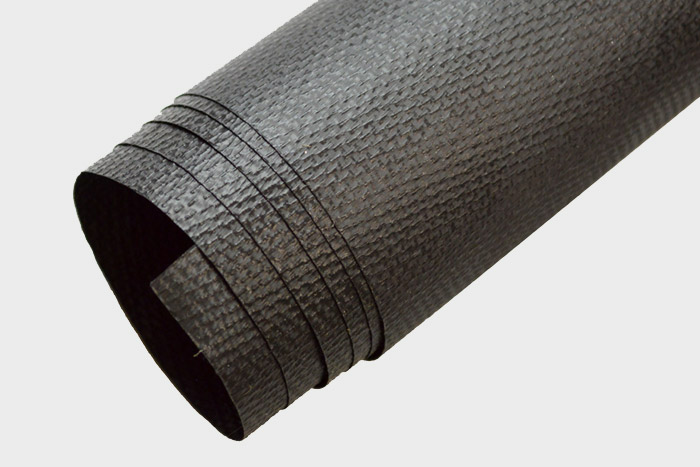

TCI’s CrossFilm™ is a 100% PTFE material that is guaranteed corrosion and contamination free, resists tearing, and has superior flexing capabilities compared to other PTFE products. CrossFilm™ can be heat-sealed and is unaffected by UV exposure or moisture. Read more »

Floating Roof Seals

TCI manufactures state-of-the-art PTFE/fiberglass composites and 100% PTFE CrossFilm™ materials for floating roof seal manufacturing companies. Applications where TCI’s materials are used include vapor barriers and seals, coverings, wipers, wiper tips, leg socks, bladders, gauge pole sleeves, tubes, strut coverings, tank linings, and geomembrane liners. All floating roof seal materials and products are unaffected by exposure to UV and contain anti-static properties.

TCI’s unique all-PTFE CrossFilm™ material solutions allow for guaranteed corrosion-free performance and long-term non-flammability retention, regardless of the chemicals within the tank. CrossFilm™ materials also have superior flexing properties, maintained non-porosity traits, and minimized permeation levels compared to fiberglass-reinforced materials.

Because elastomeric products are chemically susceptible and degraded by UV, the floating roof seal industry has advanced to using PTFE-based materials for long-term success in floating roof seal applications.

Related Products

TCI’s CrossFilm™Wiper Seals are the ideal long-term, cost-effective tank wiper solution. Unlike urethane wipers, CrossFilm™ Wiper Seals are unaffected by UV and chemical exposure, making them incredibly versatile for all types of storage tanks.

Data Sheets

TCI’s CrossFilm™ Leg Socks are the ideal long-term, cost-effective solution to reduce hydrocarbon emission from storage tank floating roofs. Unlike urethane leg socks, CrossFilm™ Leg Socks are unaffected by UV and chemical exposure, making them incredibly versatile and suitable for all types of storage tanks.

Data Sheets

TS™ is a PTFE/fiberglass composite engineered for wet or dry service in above ground storage tanks. PTFE films are laminated to both sides of a high strength fiberglass textile for enhanced protection in wet environments. This nonporous laminate is capable of withstanding severe stresses in challenging environmental conditions.

Data Sheets

Fluorotex™ is a rugged composite capable of withstanding severe stresses in challenging environmental conditions. It is easily heat-sealed in field service and has severe chemical and temperature exposure capabilities. Product variations, including special widths, are available upon request. This perfluoroplastic/fiberglass composite has been used successfully in tank sealing service since 1987.