TCI’s CrossFilm™ is a 100% PTFE material that is guaranteed corrosion and contamination free, resists tearing, and has superior flexing capabilities compared to other PTFE products. CrossFilm™ can be heat-sealed and is unaffected by UV exposure or moisture. Read more »

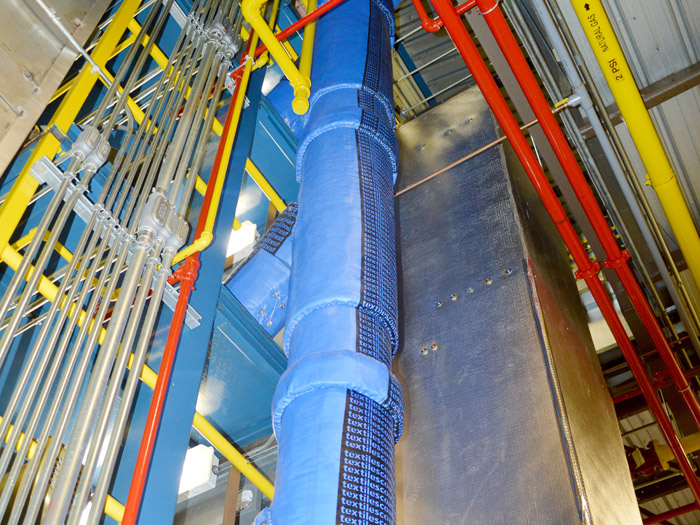

Removable Insulation Jacketing

TCI has successfully developed the broadest portfolio of materials for insulation jacketing applications, whether you call them removable insulation covers, insulation blankets, insulation jacketing, or insulation pads. TCI offers 100% PTFE materials, PTFE/fiberglass composites, and silicone/fiberglass composites, all of which are designed to survive the industrial handling and thermal/chemical exposure in any particular application.

Because of our first in fluoropolymer capabilities, TCI's materials protect industrial process equipment from fluctuating heat loss or gain while remaining immune to chemical attacks. Our range of removable insulation jacketing materials are available for a variety of different price points and have an array of properties to best serve your environment's specific needs. TCI is also an innovator for insulation jacketing technologies, including our revolutionary CrossSeal™ heat-sealed insulation jacketing. Allow TCI to help you discover the most cost-effective solution for your budget and environment.

TCI's Industry Affiliation

Related Products

Successfully used since 1985, this line of PTFE/fiberglass composites is designed for challenging insulation jacketing applications. Incorporating a proven coating technology for industrial fabrication, EJ™ products have severe chemical and temperature exposure capabilities. All EJ™ products are easily sewn.

Data Sheets

This CrossFilm™ laminate is designed for the most challenging applications. Using a proprietary hybrid of PTFE film and fiberglass, TCI's Hybrid™ material will simulate an all-PTFE laminate with the stretch and minimal elongation of a fiberglass reinforcement. It is ideal for high temperature service and wet, chemical environments. The tent-like texture and flexibility make it advantageous for the sewing of removable insulation jacketing and its superior adhesion properties ensure Hybrid™ belting will not delaminate or blister in food service applications.

Data Sheets

Filmjac™ PTFE/fiberglass composite materials are designed for harsh, wet insulation jacketing applications. PTFE films are laminated to one or both sides of a composite for enhanced chemical protection.

Data Sheets

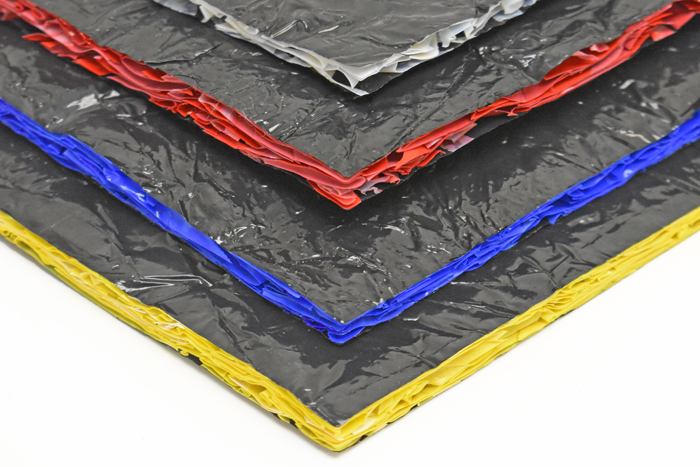

This silicone/fiberglass composite with a proven flexible coating is engineered for standard duty insulation jacketing applications. With great tear, puncture and abrasion resistance, it is liquid repellant, flame retardant and easily sewn.

Data Sheets

This silicone/fiberglass composite has a rugged and thick coating technology engineered specifically for removable pads, flanges, and valve covers. Siltuf™ 2000 has been successfully used in insulation jacketing applications since 1985. The product is flame retardant and can be easily sewn. Many colors are available.

Data Sheets

Insilflex™ is a silicone/fiberglass composite with proven flexible coating technology is engineered for standard insulation jacketing applications. It has been successfully used in insulation jacketing since 1985.

Data Sheets

Pyrojac™ consists of a woven fiberglass textile with a proprietary vermiculite coating that is engineered to withstand exposure to elevated temperatures.

Data Sheets

Tufjac™ is a silicone/fiberglass composite with a rugged coating technology, engineered for removable pads, flanges, and valve covers.

Data Sheets

Laminate engineered for ultra-clean or chemically-challenging environments

TCI’s Therma-Pure™ is a 100% PTFE insulation material. Designed for applications requiring non-contaminating and/or long-lasting insulation properties. This insulation material is unaffected by chemical and wet exposure in a pH range of 0-14.

Downloads

An economical sealing process for removable insulation service.

By combining our revolutionary CrossFilm™ material and heat-sealing technology, TCI has made heat-sealed removable insulation jacketing feasible and cost-effective. Our Cross-Seal™ insulation jacketing product keeps insulation materials dry and functional for the long-term by minimizing the possibility for corrosion under insulation (CUI). TCI’s proprietary and leak-tight all-PTFE CrossFilm™ is seamed together using a fast and effective process that simulates the speed of sewing and allows for complex shapes and three-dimensional designs. The insulation material stays dry and fully encapsulated by the CrossFilm™ material. CrossFilm™ is unaffected by chemicals, has no shelf life, and will not corrode. There is also no concern of escaping fiberglass or powders into the environment, which is critical for ultra-pure applications such as clean rooms, food plants, and pharmaceutical plants. The CrossFilm™ material is ultra-light and ultra-flexible, with sufficient heat-sealed strength at the straps to anchor heavy insulation pads. Cross-Seal™ is designed and sold only to insulation jacketing manufacturers.

Downloads